Wafer Metrology

| Wafers ultimately have very smooth surfaces, so high-resolution sensors based on coherence scanning (white light) interferometry with piezo are used for corresponding measurement tasks. While sensors with just one lens (smartWLI compact, smartWLI firebolt) are used in inline monitoring of individual processes, automatic wafer measuring stations are typically equipped with sensors such as the smartWLI next and smartWLI firebolt. These sensors can be equipped with different lenses and used for different measurement tasks. | contact person: Matthias Liedmann phone: +49 (0) 3677-83710-54 email: sales@gbs-ilmenau.de |

|

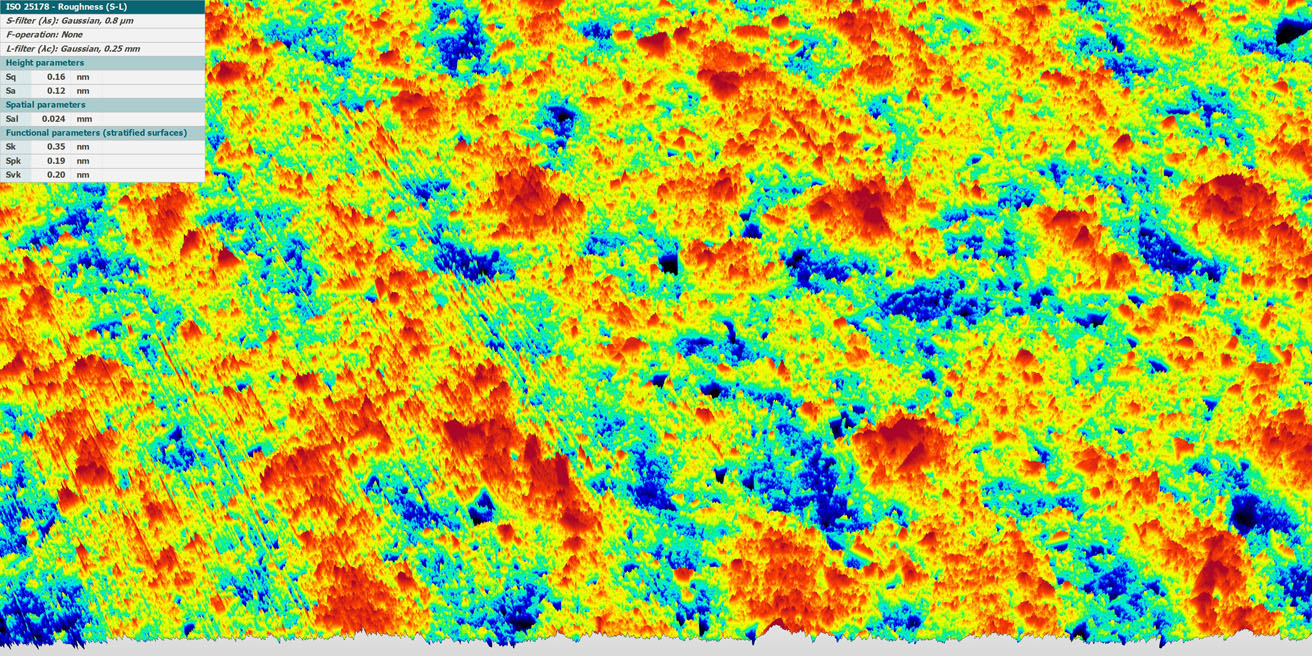

super polished SiC surface

The measurement results of such surfaces prove the outstanding resolution capacity of the smartWLI series. Even with height differences in the range of an atom diameter (1 angstrom ≙ diameter of hydrogen atom ≙ 0.1 nm), surface structures can be clearly displayed, many measurements can be joined together without offset using smartSTITCH and processing errors such as small scratches and the dominant waviness can be clearly displayed and evaluated.

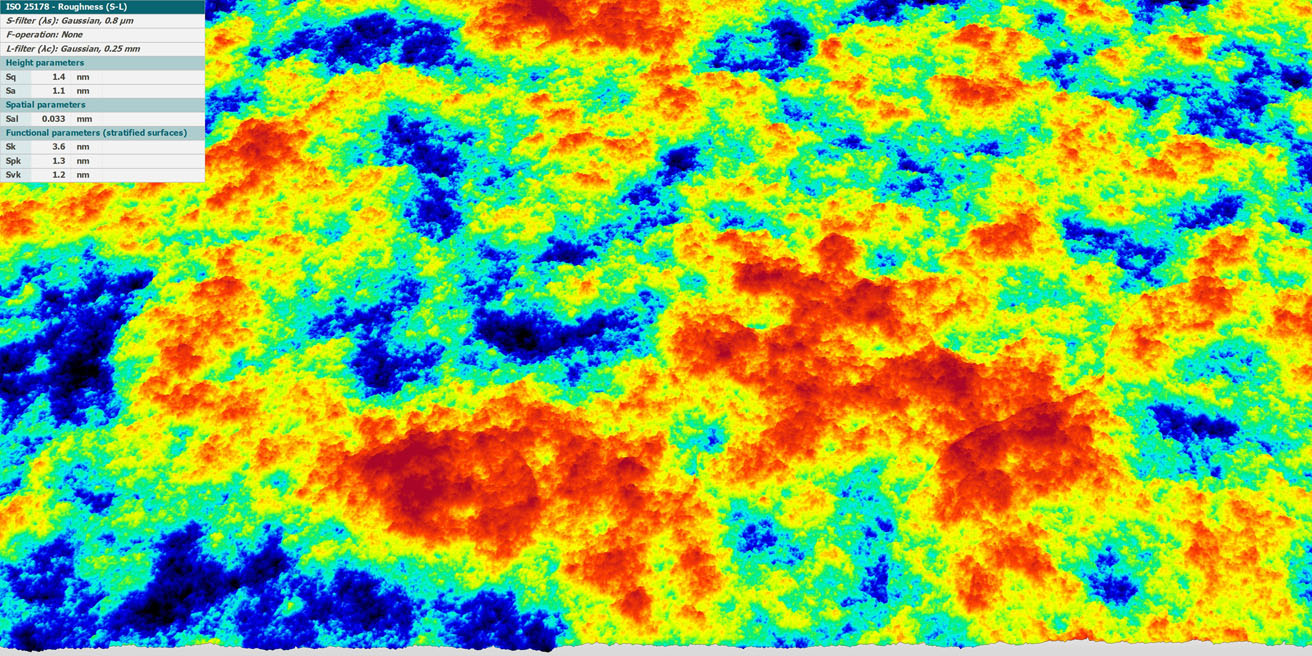

polished wafer

On the one hand, the polished wafer has locally very finely structured surface structures, but on the other hand it also has micro-waviness. Both properties are functionally relevant, so that high-resolution measurements, for example with a 50x objective, should be used for quality monitoring with the measurement of larger areas using, for example, a 5x objective.

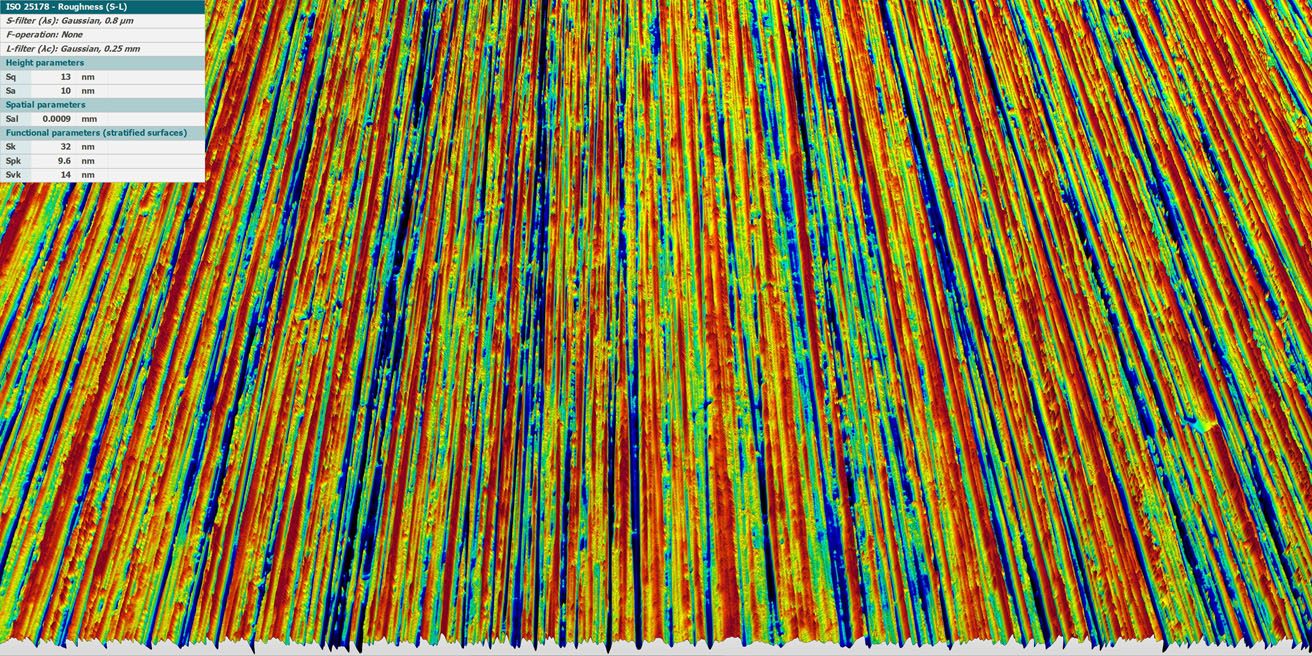

grind wafer

The grind wafer has a very fine structured surface. This can be assessed by the autocorrelation length Sal. Sal 0.9 µm (standard reference limit s = 0.2) means that the corresponding measuring device must also have a very high resolution. The lateral period limit DLIM (see ISO 25178-604) should be used to evaluate the structure resolution. The smartWLI dual and smartWLI nanoscan systems with a 50x objective offer DLIM < 0.9. For all other systems, a 100x lens must be used for correspondingly finely structured surfaces.

Black Silicon

“Black Silicon” surfaces have very small structures with a very high aspect ratio. Corresponding surfaces can only be measured using the smartWLI nanoscan and smartWLI dual systems with a 115x objective. The use of FFT-based quality monitoring algorithms eliminates effects caused by interference and multiple reflection between the structures in other optical measuring devices and coherence scanning (white light) interferometers without corresponding algorithms.

structured wafers

With measuring point distances from 0.03 µm and a lateral period limit DLIM < 0.5 µm, small features or test structures on wafers can be measured quickly and easily and with extreme height resolution.