Laser structures surfaces

| Lasers are increasingly being used to specifically improve the functional properties of material surfaces. Corresponding surface structures usually must be checked three-dimensionally. The smartWLI sensors and measuring devices are particularly suitable because, due to the high acceptance angle, lenses with low resolution can also be used to evaluate significantly large areas with a single measurement. | contact person: Matthias Liedmann phone: +49 (0) 3677-83710-54 email: sales@gbs-ilmenau.de |

|

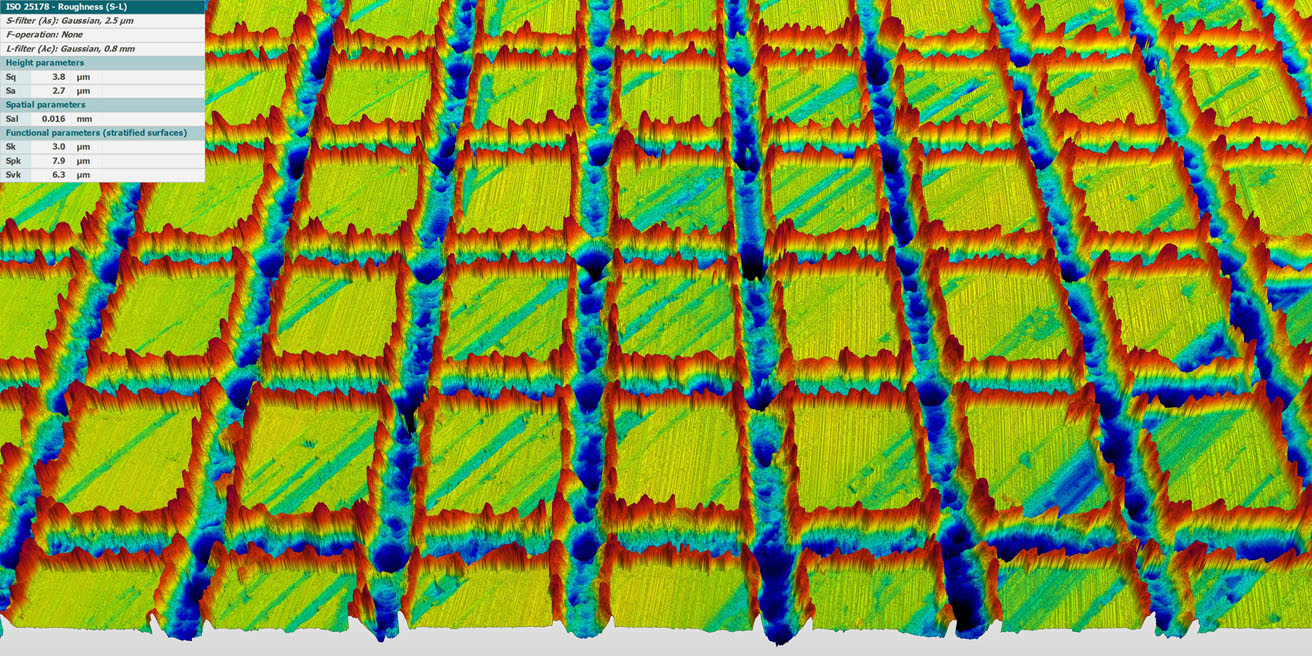

crossed laser lines

In addition to the laser lines, there is a sharp-edged “laser ridge” that increases the friction on these friction surfaces. In this specific case, this effect is used to reduce the size of the friction surface and the entire component. Since this is a safety-relevant component, 100% inspection is required. A smartWLI extended range with 10x lens is used here. The speed of the sensor enables inline use without vibration dampening.