Galvanic deposit surfaces

| Galvanic surface coatings (named after the Italian naturalist Luigi Galvani) include several different processes in which metal is deposited onto another surface. Visual and functional properties often must be guaranteed and monitored. | contact person: Matthias Liedmann phone: +49 (0) 3677-83710-54 email: sales@gbs-ilmenau.de |

|

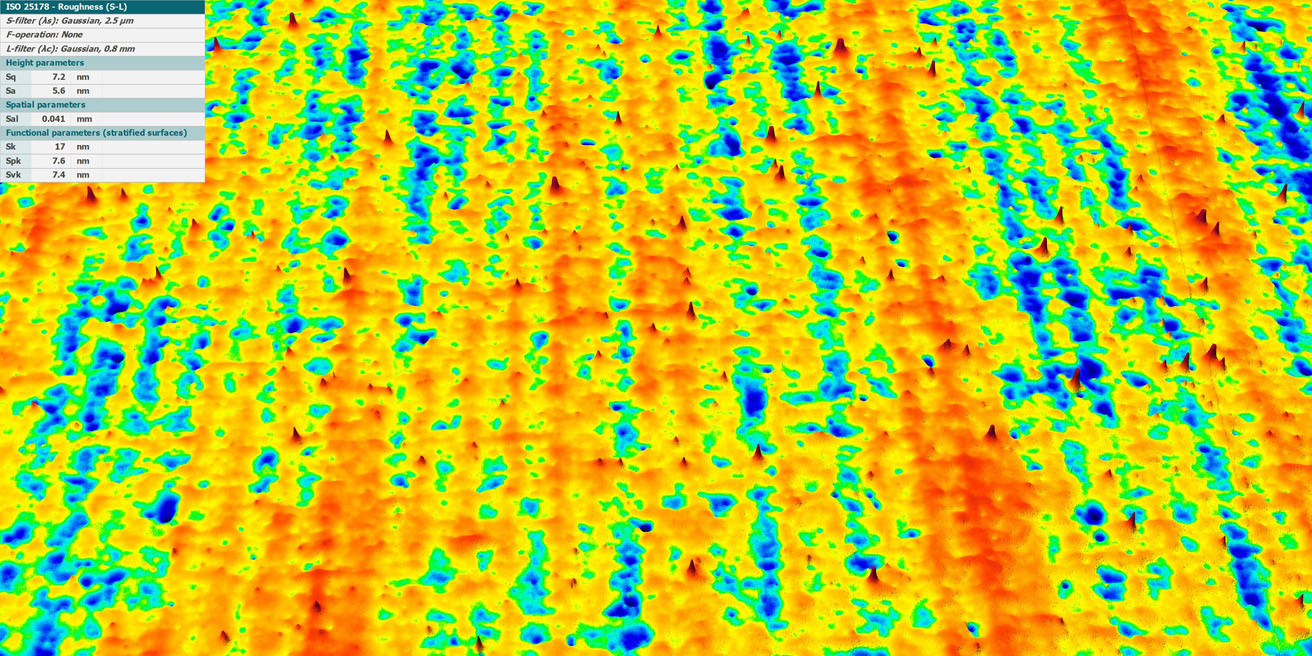

chrome plated surface

Chrome-plated surfaces are very smooth and shiny. Scoring and points caused by the deposition process can affect the shine. The smartWLI compact system with a 50x lens was used for the corresponding measurements.

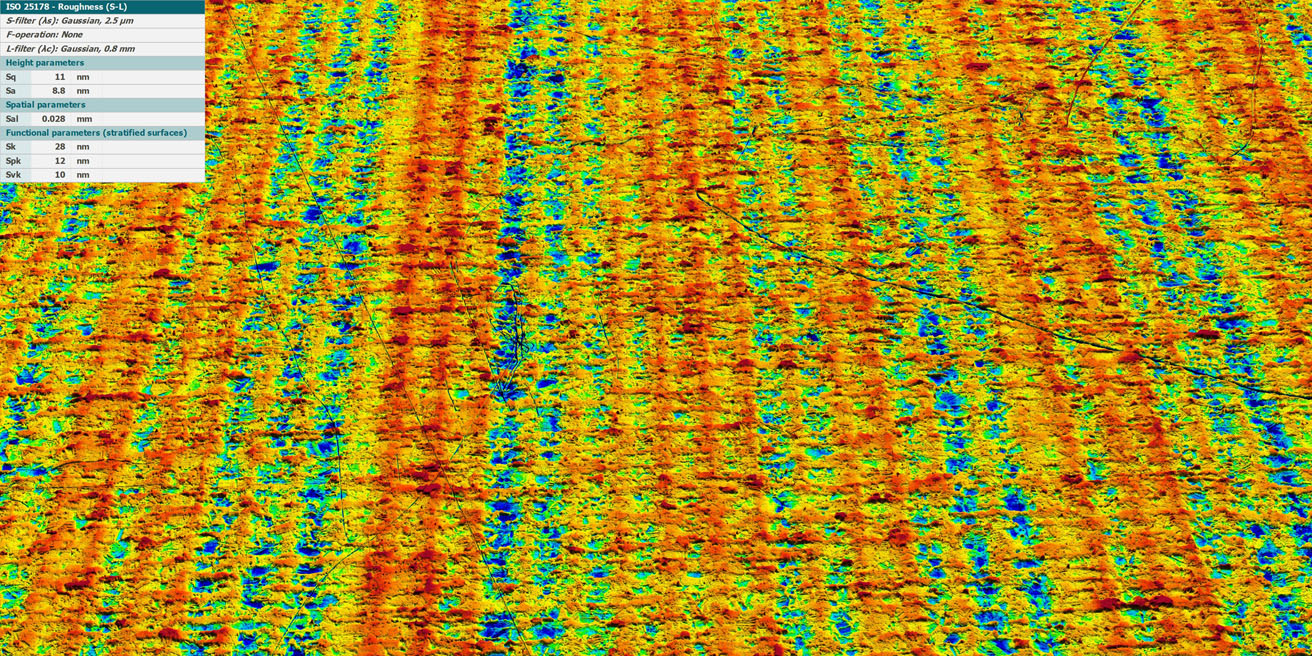

chrome plated surface with scratches

The smartWLI compact system used with a 50x lens has a significantly higher resolution than tactile measuring devices and can easily resolve small surface damage. The high measuring speed allows the measurement of sufficiently large measuring areas with several hundred individual measurements in just a few minutes.

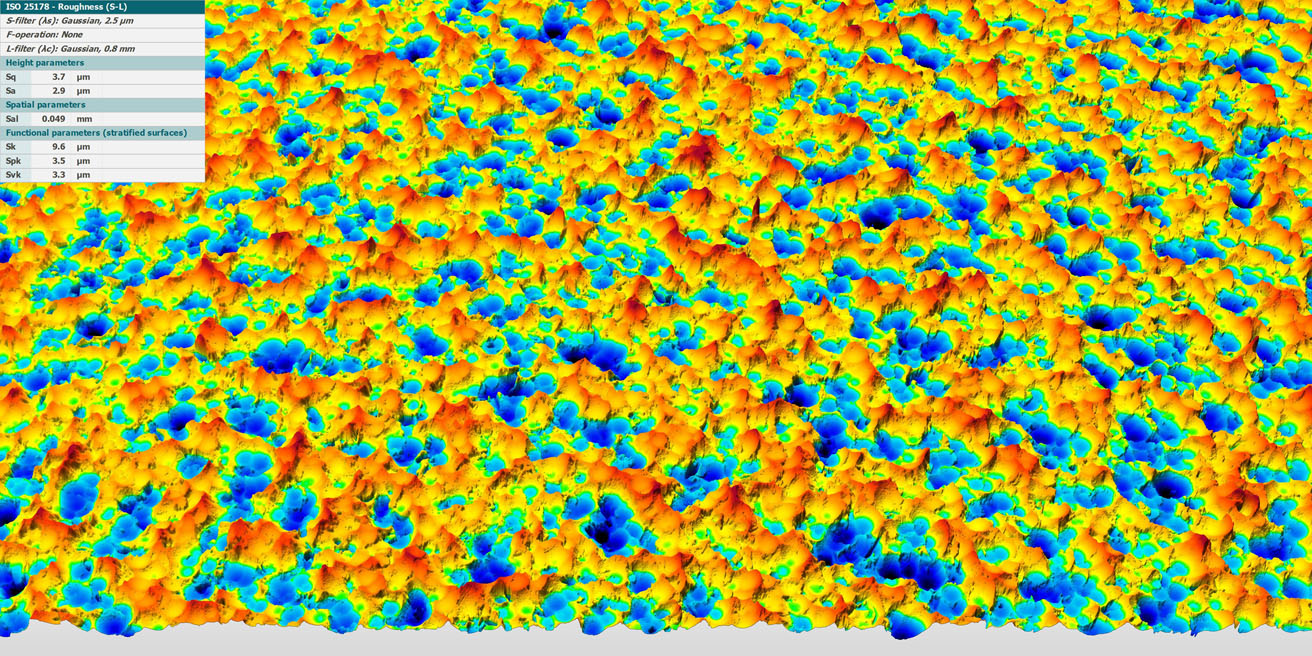

glass blasted and anodized aluminum surface

This anodized aluminum surface has a transparent aluminum oxide layer several µm thick. The smartWLI extended range uses algorithms that ensure that the signal of the first reflection on the transparent cover layer is used to correctly measure the surface. Measurements ensure the consistency of the surface finish without visible and disturbing batch differences.