Optical components

| Optical components have very smooth surfaces and, with a few exceptions, must be measured over large areas. High-resolution sensors with piezo are used. In quality control, a sensor with an adapted lens with moderate magnification, such as the smartWLI compact or the smartWLI firebolt, is often sufficient. | contact person: Matthias Liedmann phone: +49 (0) 3677-83710-54 email: sales@gbs-ilmenau.de |

|

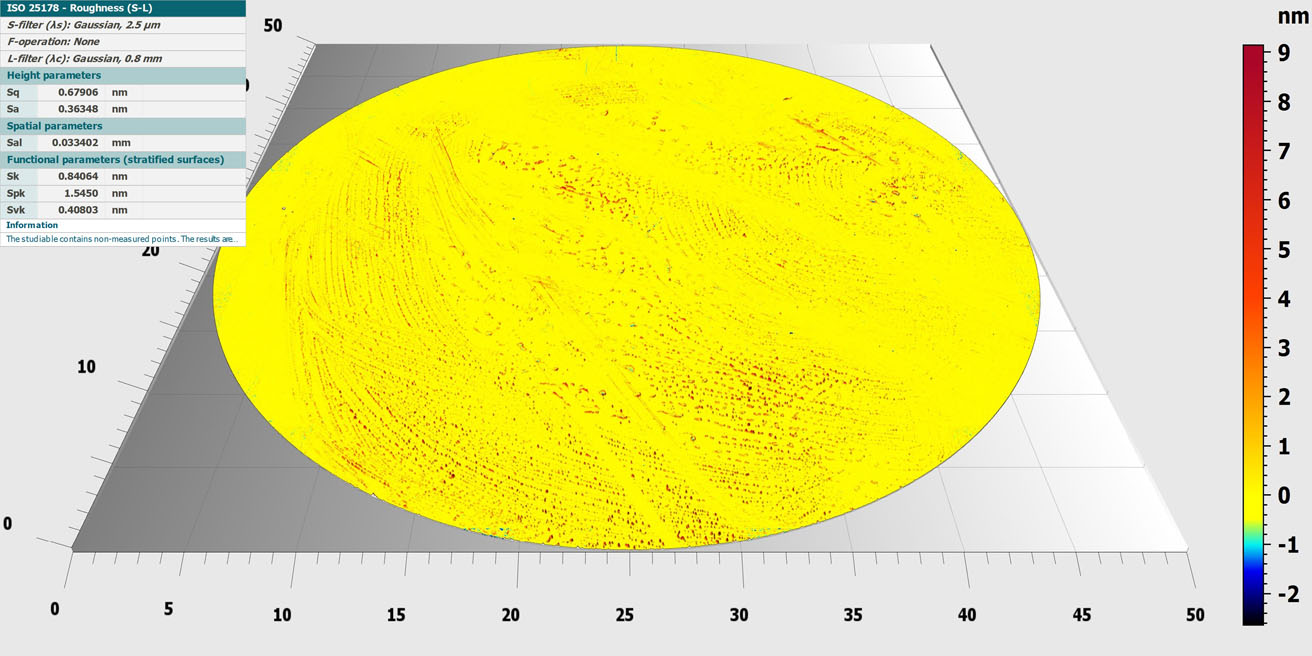

cleaning of optical components

Cleaning optics is an important step in achieving optimal performance, coating results, etc. Even small drops of dried cleaning fluids can leave streaks several nm high on the surface.

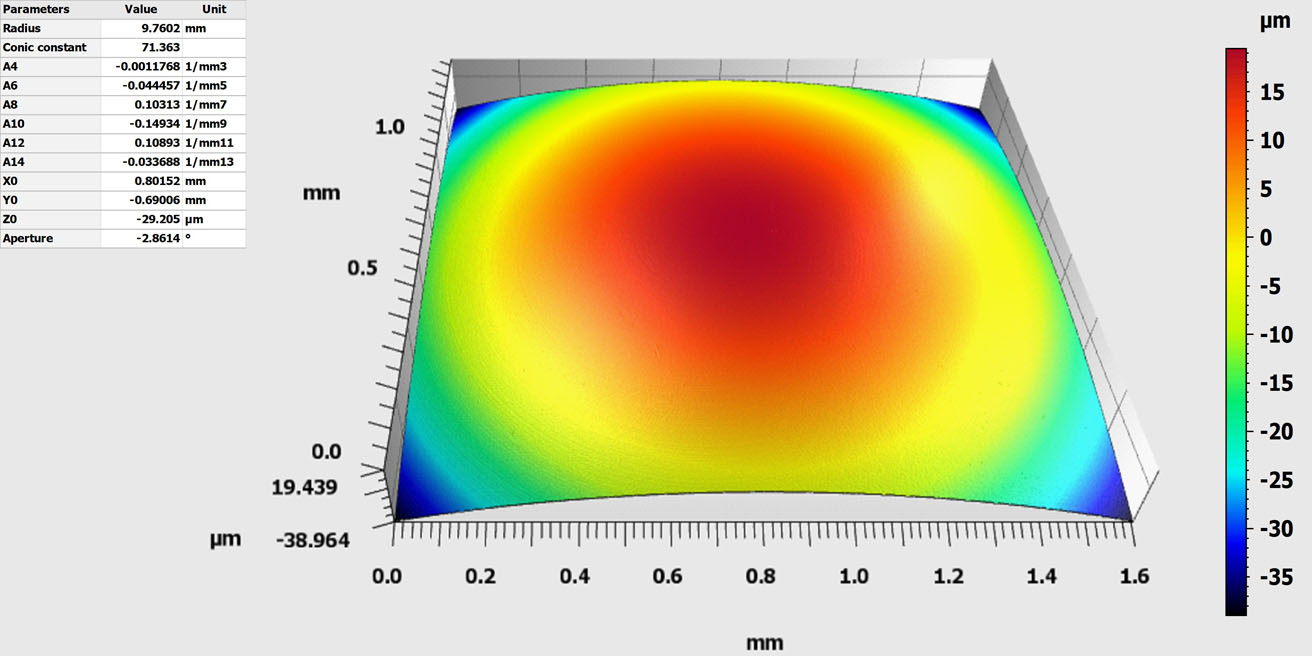

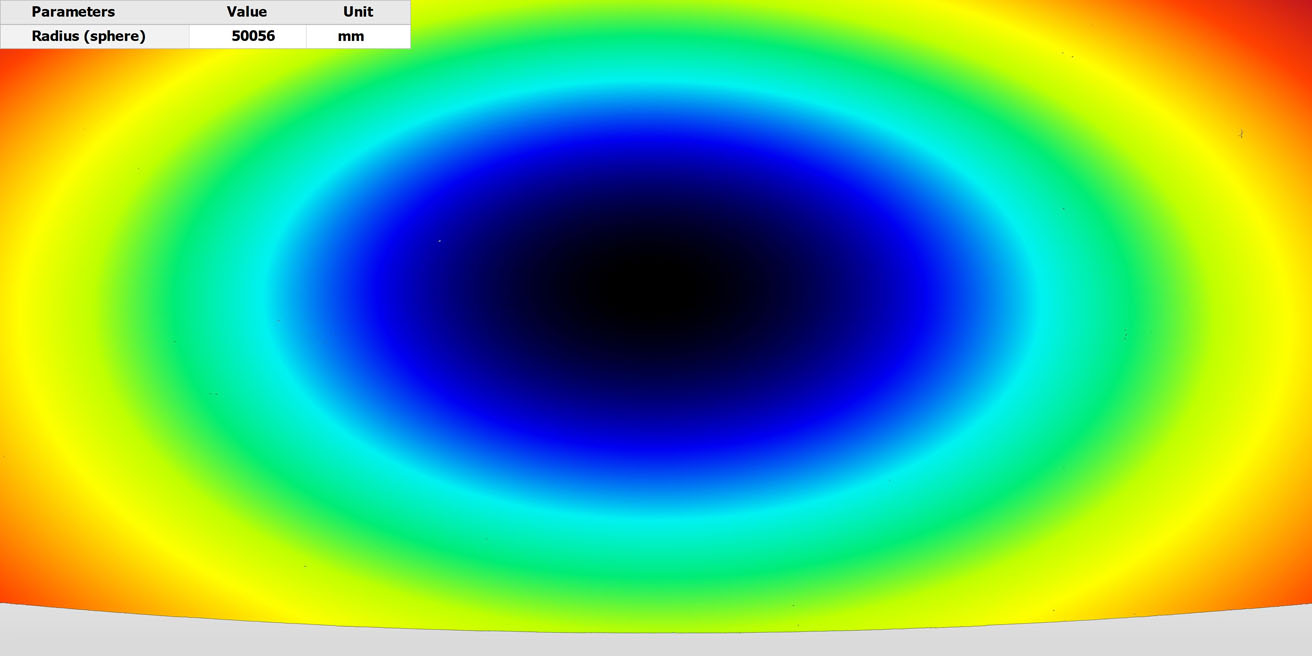

small, diamond turned lens

Precision measurements allow the determination of lens parameters as well as the combined evaluation of shape and surface roughness.

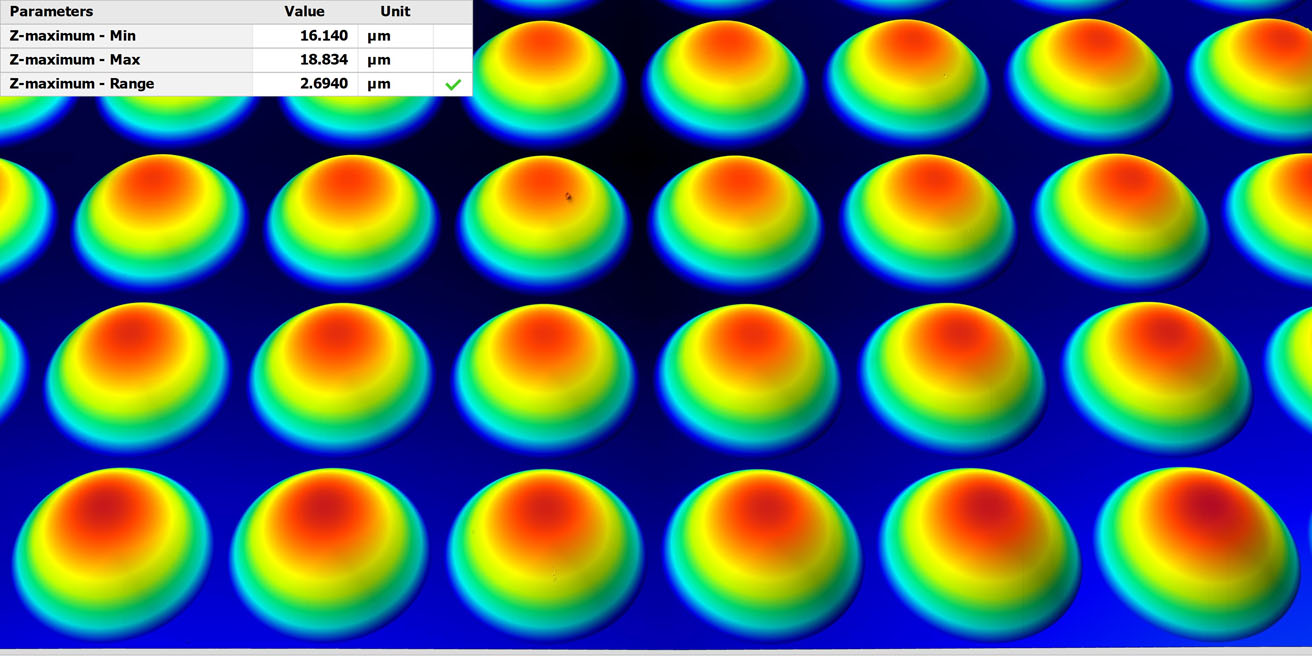

micro lens array

Arrays with many microlenses must be measured quickly to be able to measure and evaluate all lenses within a reasonable amount of time or at least a sufficiently large sample.

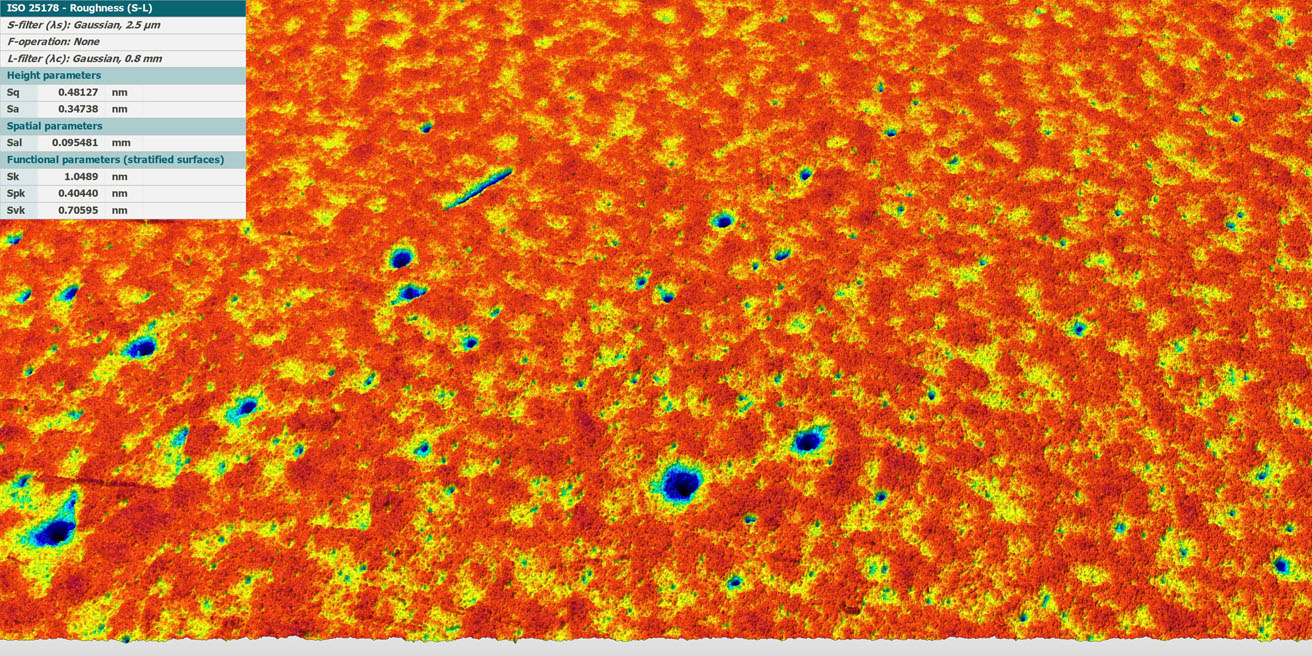

polished glass surface

High-quality optics like this prism must be checked over a large area for the smallest defects. For data sets with several 100 to several 1000 individual measurements and many 100 million measuring points, special algorithms can be used to make even small defects visible and to enable them to be specifically examined.

mirrors for high power lasers

Mirrors for high-power lasers with very large focal lengths must be manufactured extremely precisely. Sensors such as the smartWLI compact and the smartWLI firebolt with a 2.5x lens combined with a high-resolution tilt table are used to measure shape. Optimized methods for sensor calibration and stitching enable the highest measurement accuracy.

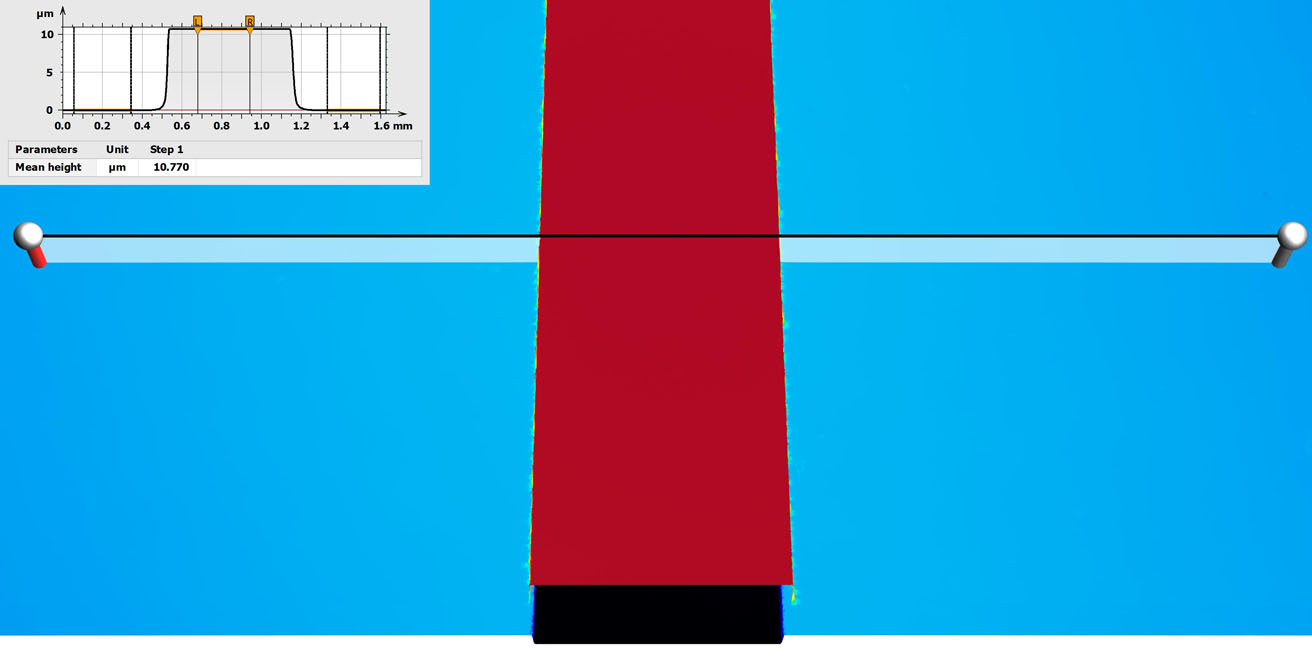

measurement of transparent layers

Measuring the thickness of transparent layers can often be done in the same way as measuring a step height. However, with thin transparent layers on a reflective sur-face, both the surface of the transparent layer and the surface underneath will reflect light back. Surface roughness, layer thickness and refractive index have a major influence on which signal is more pronounced. Within a certain thickness range, both signals can be recognized and separated. For this purpose, optional software can be used that makes it possible to recognize both layers and determine the thickness.