smartWLI extended

smartWLI extended – universal sensor for measuring labs

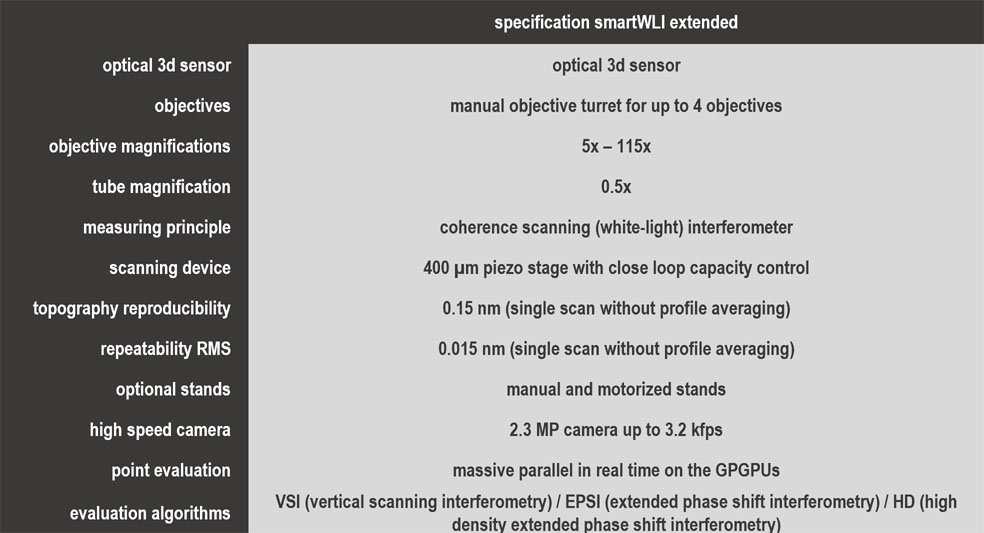

The manual turret simplifies the operation of the fast optical 3d sensor. The 400 µm piezo stage enables the meas-urement of extreme smooth surfaces. The turret allows the easy localization of small features using low magnifica-tion objectives with instant exchange of the objective for measurements.

A wide range of various stands and granite portals can be used to build up optical 3d profilers from GBS fitting to requirements. Alternative the SDK including C++ and C# libraries as well as source code for sample application can be used to integrate the sensor into customized measuring stations.

Using coherence scanning (white-light) interferometry to measure roughness and micro geometries

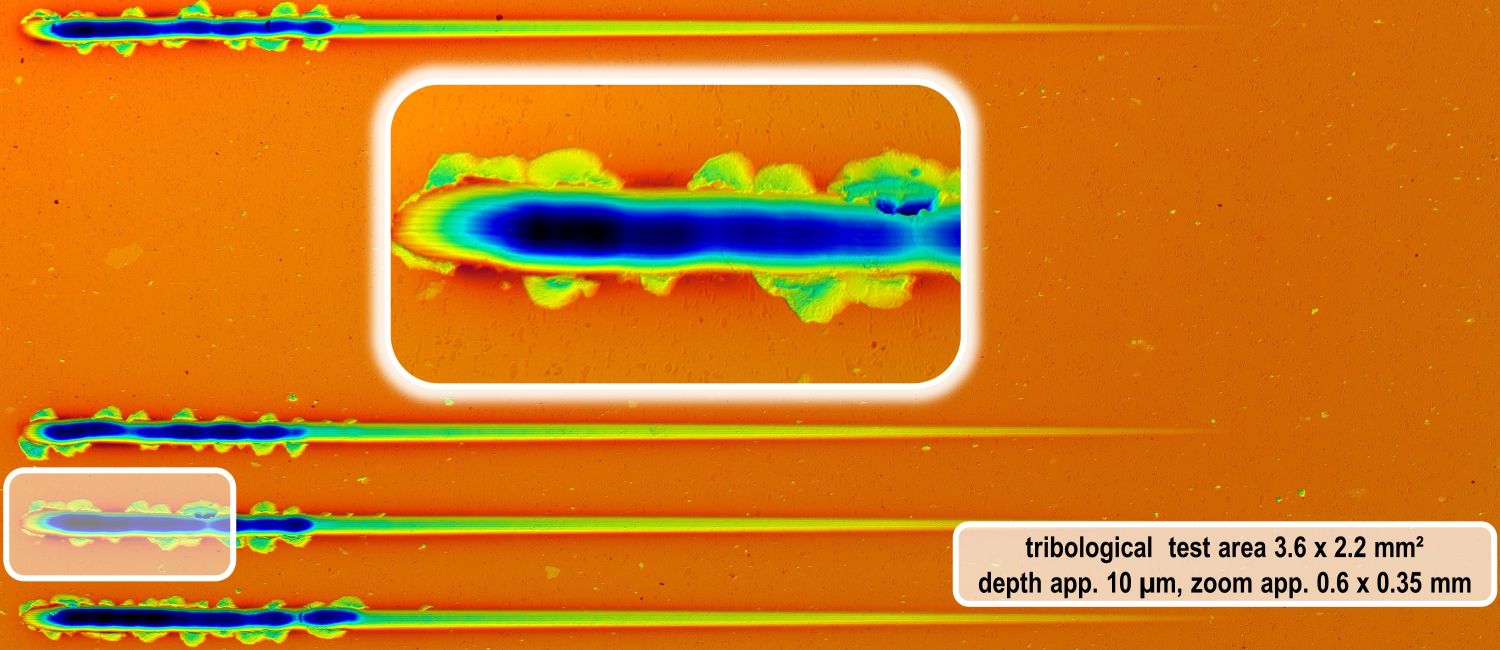

Coherence scanning (white-light) interferometry provide a much higher resolution than competitive optical 3d measuring principles as confocal microscopy, focus variation, chromatic confocal sensors, fringe projection or laser triangulation sensors. As microscopical optical measuring principle the GBScanner can be configurated using interference objectives with magnification from 2.5x up to 115x. Structures starting from lateral seize of app. 0.3 µm can be resolved. The upper limit is several mm² for single scans and several cm² for stitched areas.

Advantages of smartWLI sensors and optical profilers compared to other coherence scanning (white-light) interferometer

High speed cameras combined with massive parallel data processing allows to accelerate the data acquisition and evaluation processes and make the systems robust and less sensitive against vibrations. The acceleration enables data acquisition and stitching of several 100 single scans with typical cycle times of 1…3 seconds per single scan. The data processing including contrast enhancement, model-based signal correction and data quality surveillance enables to pick up weak signals on high sloped areas.

Direct contact to our Team:

EMail: sales@gbs-ilmenau.de

Phone: +49 3677 83710 54