Measurement of cutting edges

| The high computing power of the GPGPUs (general purpose graphic processing units) used in the smartWLI allows the use of algorithms that can evaluate even very small signals. This increases the acceptance angle and allows steep edges to be measured. This also allows cutting edges to be measured without having to use sensors based on focus variation with external lighting. This results in a much higher resolution of details compared to alternative sensors. | contact person: Matthias Liedmann phone +49 (0) 3677-83710-54 email: sales@gbs-ilmenau.de |

|

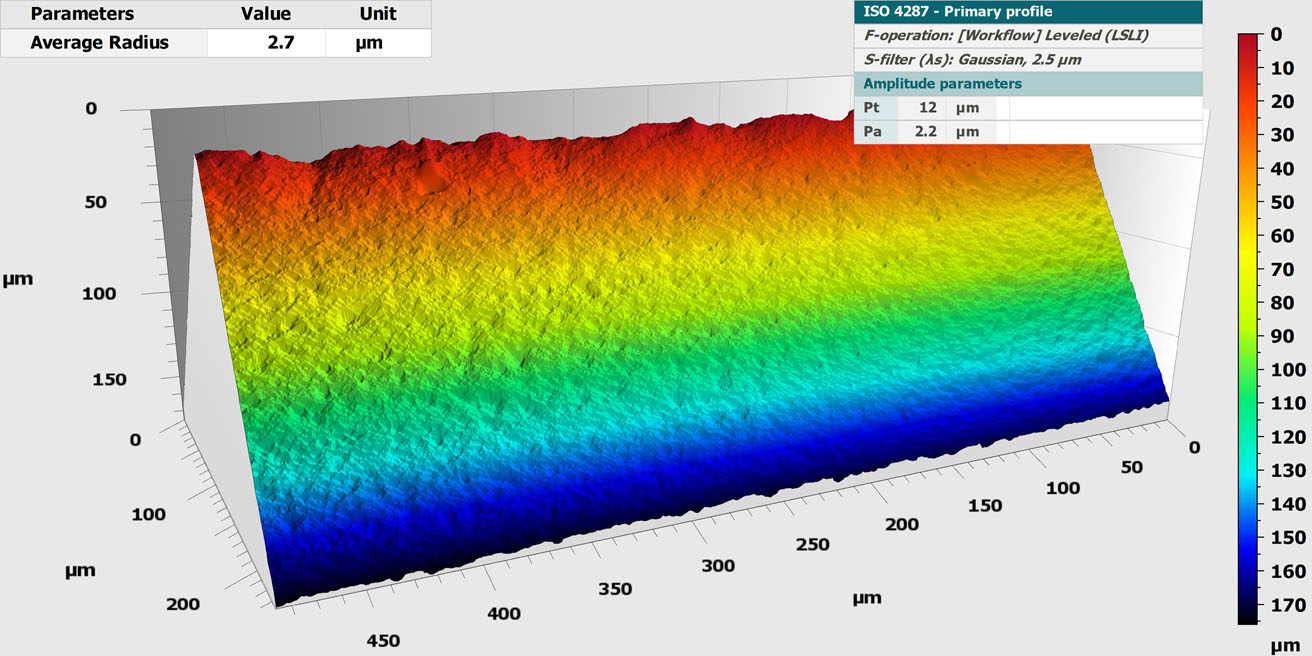

pcd (poly crystalline diamond) insert

PCD indexable inserts have very sharp cutting edges with edge radii sometimes below 1 µm, whose microgeometry can no longer be resolved with measuring devices based on the focus variation. 50x lenses should be used to measure these tool edges.

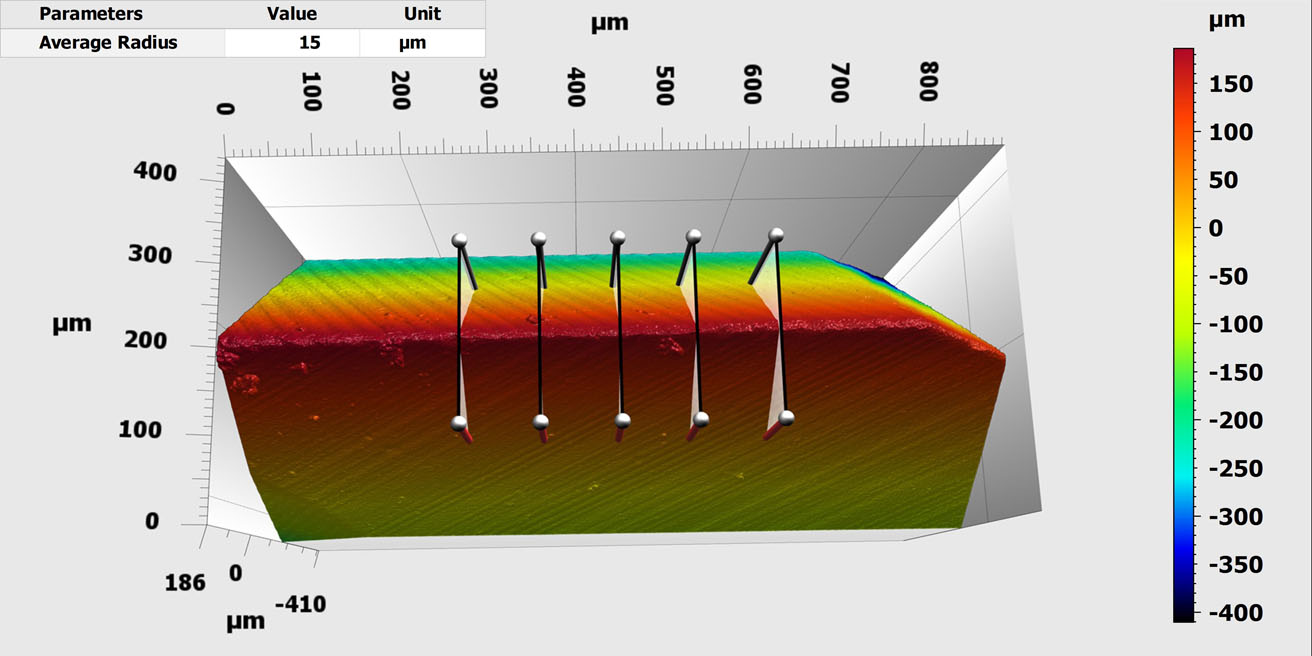

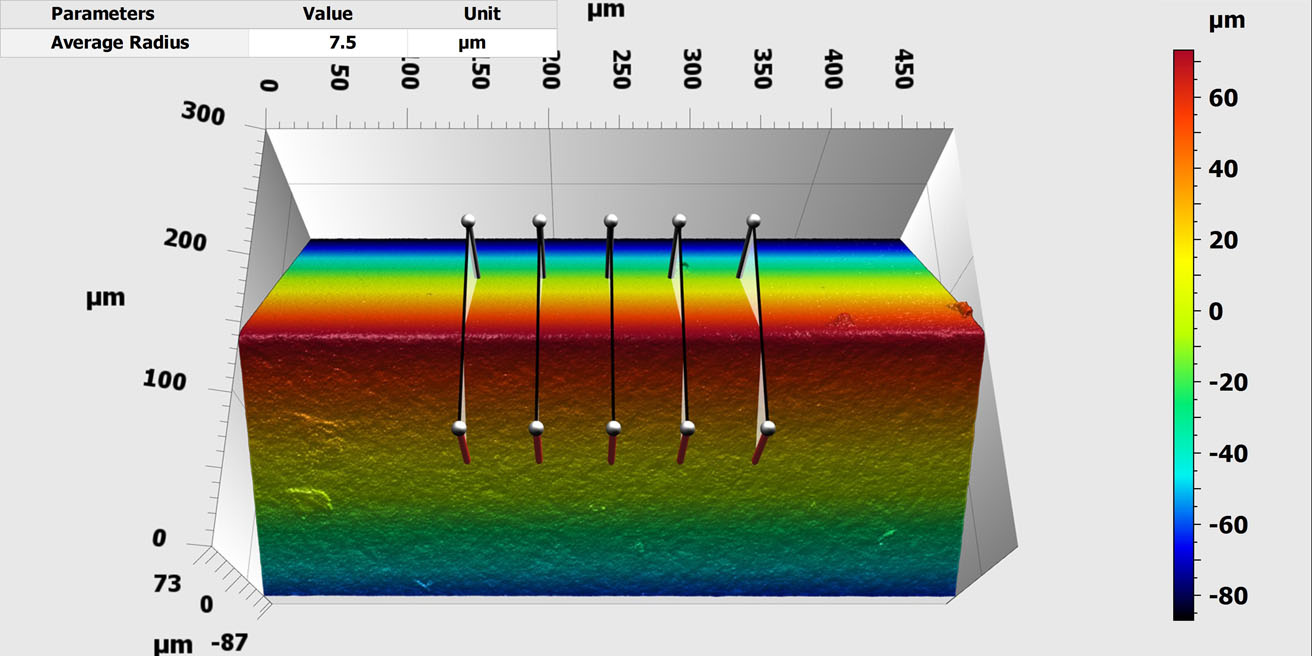

main cutting edge end mill

A 20x objective can be used for appropriate measurements. The edge can be evaluated automatically using the contour analysis of the MountainsMap software package.

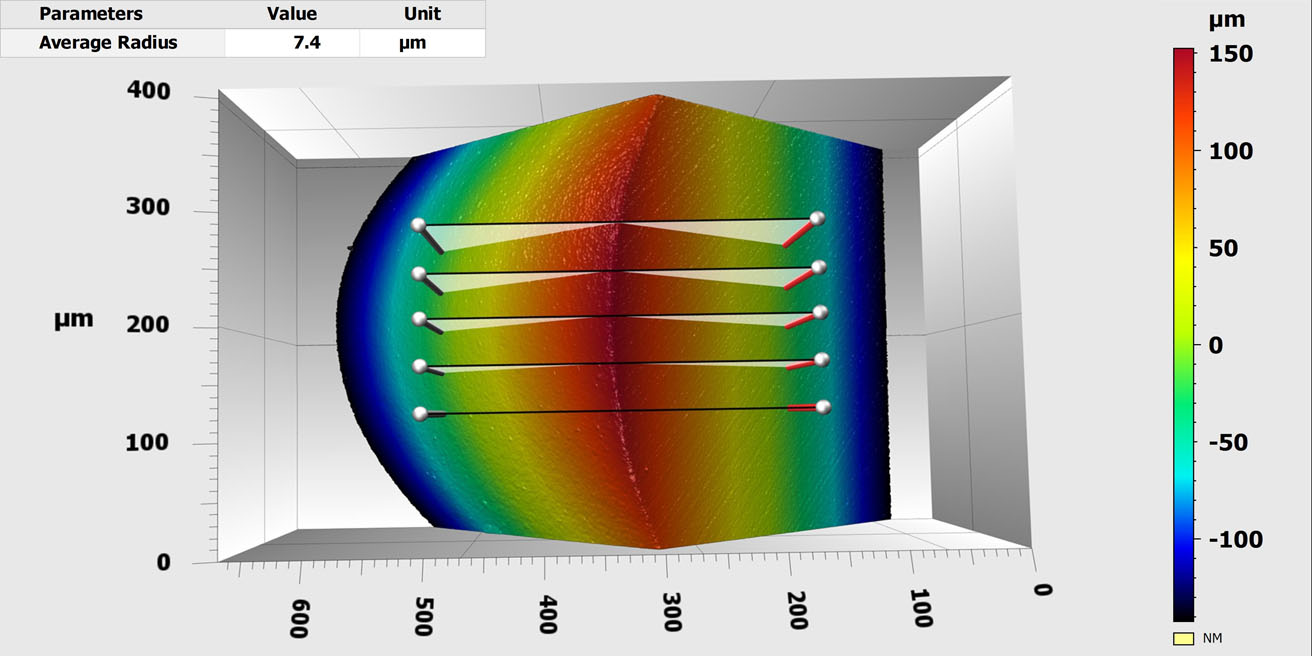

cutting edge of an insert

A 20x objective can be used for appropriate measurements. The edge can be evaluated automatically using the contour analysis of the MountainsMap software package.

edge master

On the one hand, radii of calibrated edges can be reproduced and on the other hand, the smartWLI systems offer the accuracy to provide corresponding standards with a factory calibration.