Tribology

| Particularly when corresponding tasks are being investigated in institutional research, the combination of a smartWLI compact with a 50x objective offers the necessary resolution to achieve the necessary results. The high measuring speed of approx. 1 ... 3 s for a single measurement allows larger areas to be recorded with several 100 measurements in just a few minutes. | contact person: Matthias Liedmann phone: +49 (0) 3677-83710-54 email: sales@gbs-ilmenau.de |

|

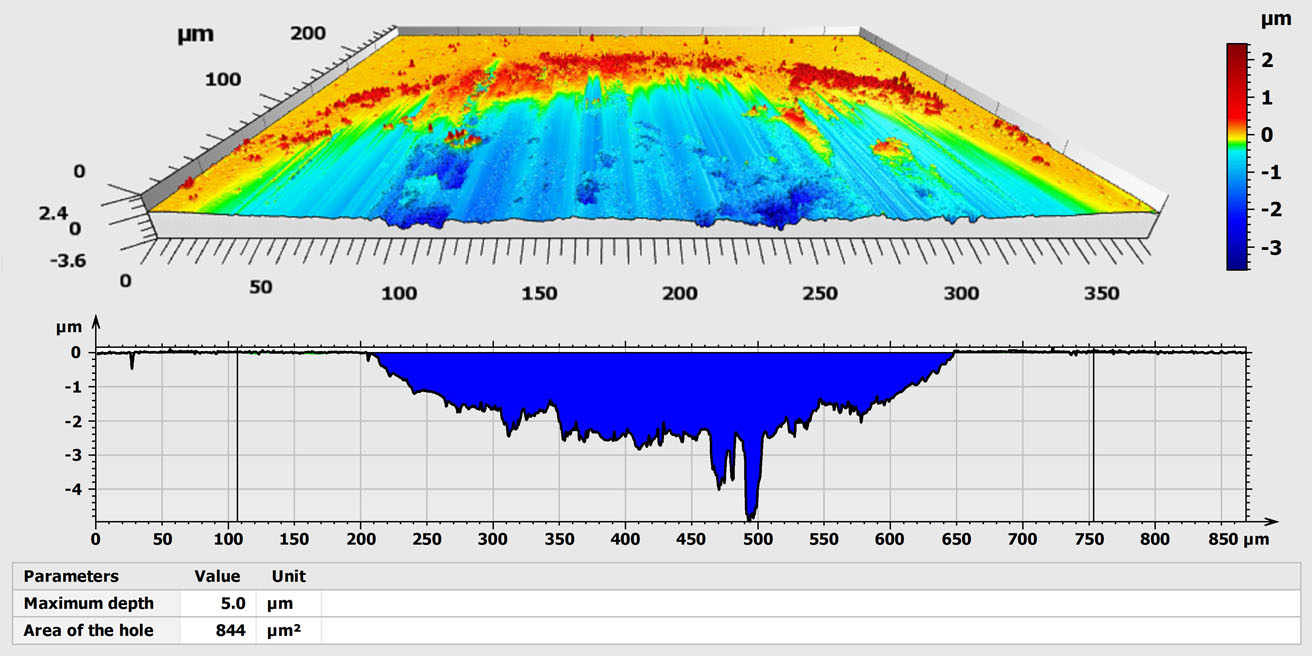

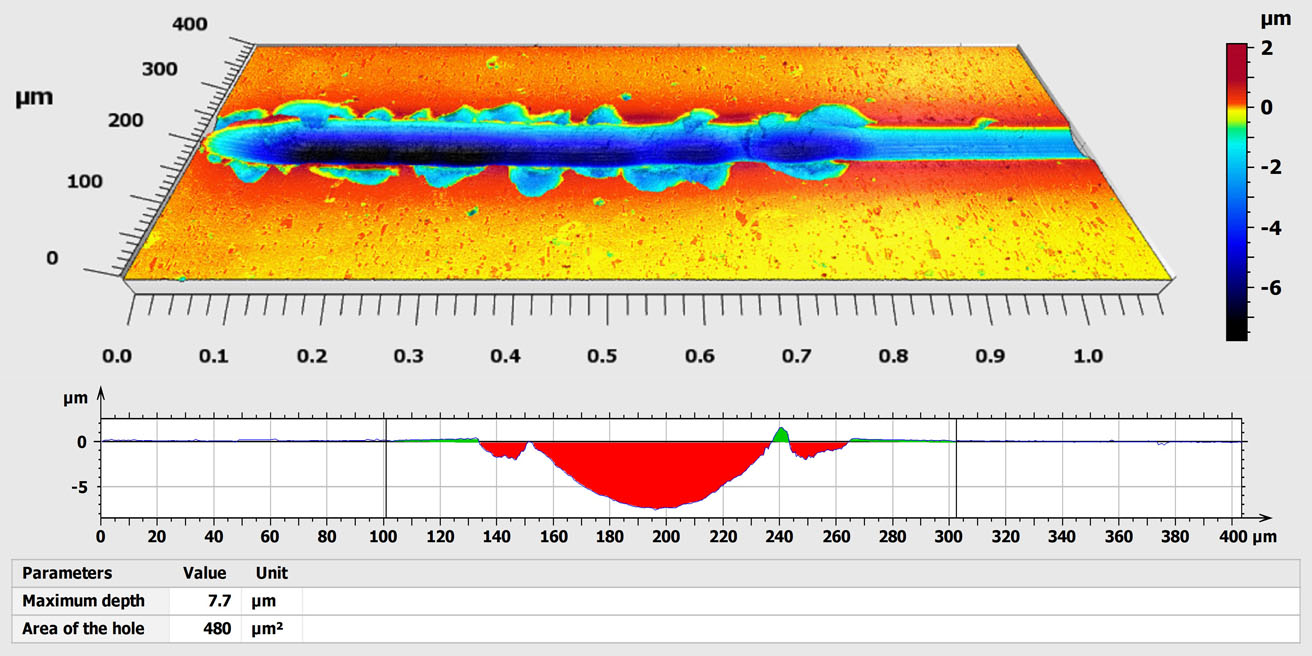

evaluation of a scratch test

The evaluation functions of the MountainsMap software allow the quick and easy analysis of wear volumes and removal areas.

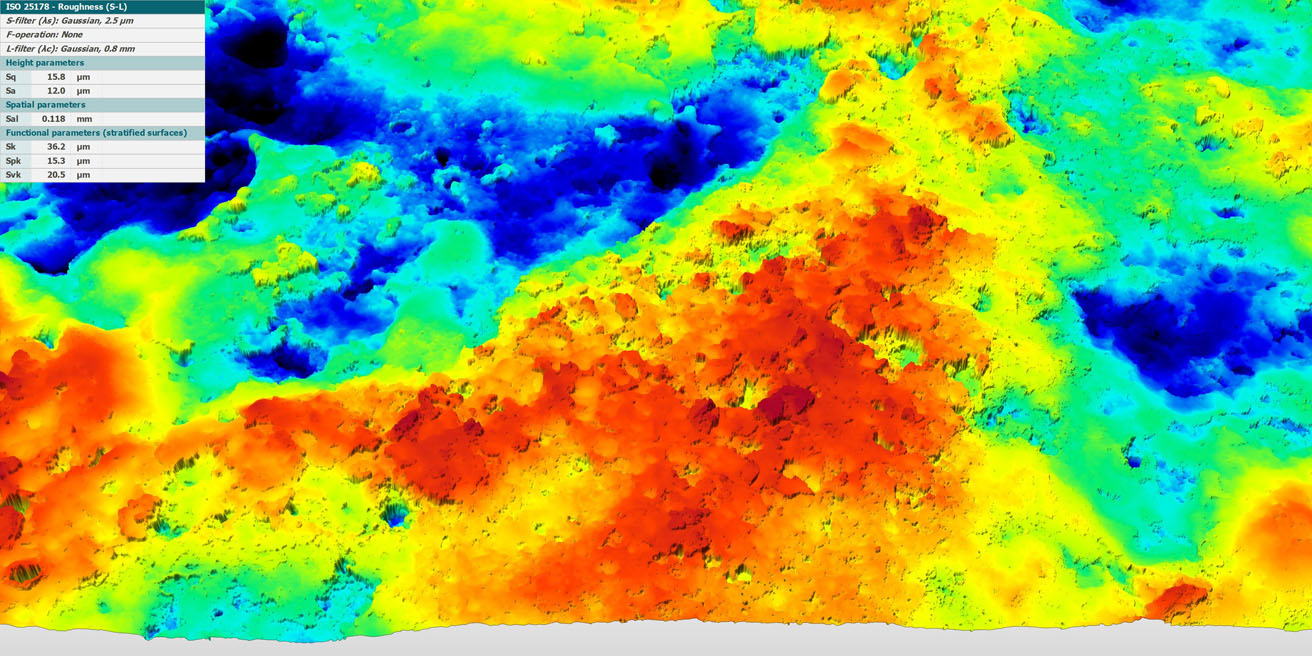

spark erosion on an electrode

The surface shows the crater structures typical of spark erosion. If the wear process has progressed so far, external reference surfaces must be used to determine the depth and volume of the material being removed.

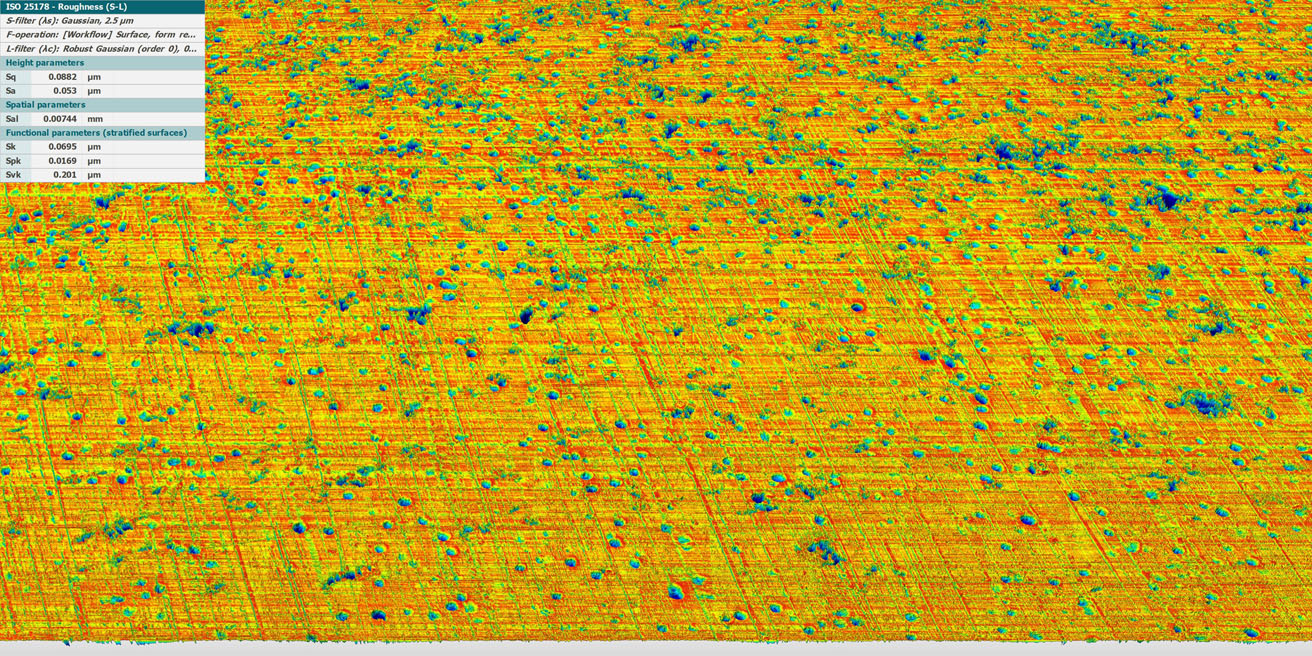

evaluation the wear on a ball bearing

The evaluation of ball bearing surfaces requires the measurement of the smallest surface structures on inclined surfaces. For this purpose, the smartWLI compact system with 50x objective was used.

evaluation of a protective coating

Tests show the level of stress at which the protective layer breaks through and flakes off. High-resolution measurements of larger areas make it easier to understand the processes that occur.