Micro geometries

| In addition to surface measurements, the measurement of microgeometries is, on the one hand, a typical measurement task, but on the other hand, the requirements and tasks are very diverse, so that generalization is only possible to a limited extent. We would be happy to advise you on this. If in doubt, simply use the option of free test measurements. | contact person: Matthias Liedmann phone: +49 (0) 3677-83710-54 email: sales@gbs-ilmenau.de |

|

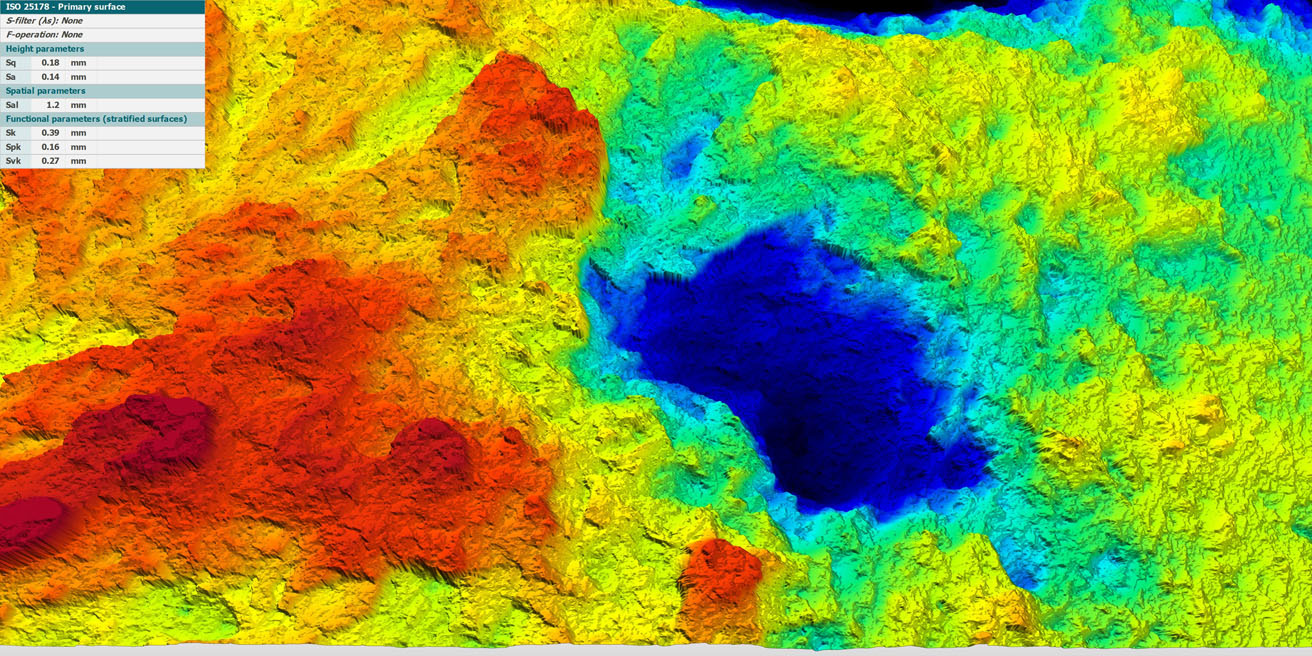

crack surface of a connecting road

Breaking a finished connecting rod to insert the crankshaft is an inexpensive alterna-tive to precision manufacturing two halves of the split connecting rod bearing. However, the broken surface must also meet certain requirements and be evaluated. Since a larger area with steep sides and highly fissured surfaces requires fast and high-resolution measuring devices.

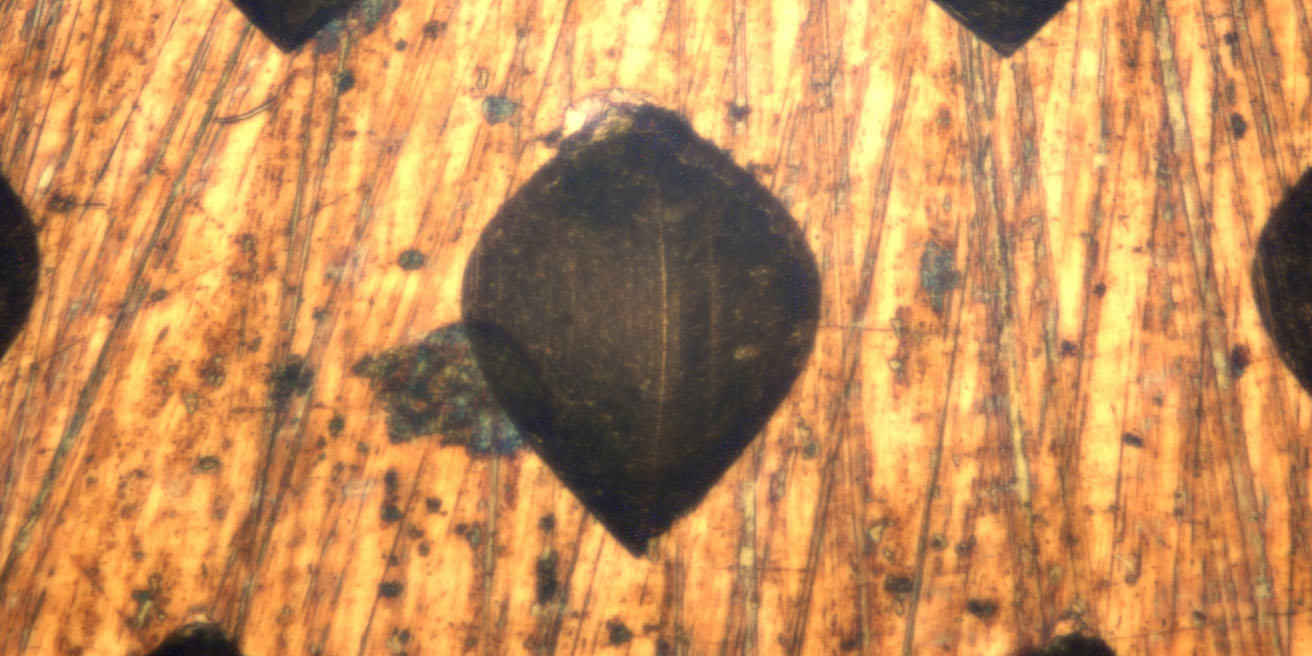

Graver engraving of a printing cylinder

Corresponding printing cells are used to transfer color from the printing roller to the paper and their size determines the color saturation. To be able to use the system to assess colored surfaces, a color camera was used.

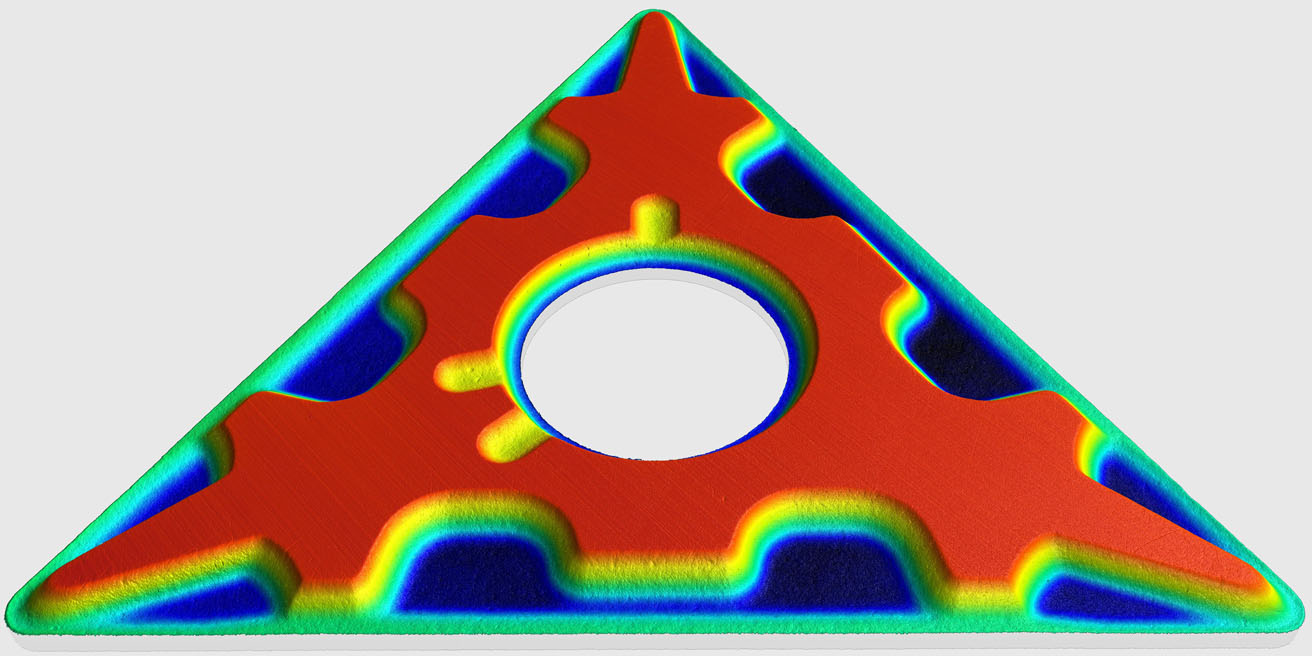

insert

The high measuring speed and the extended acceptance angle allow the combined measurement of shape and surface roughness up to an object size of a few cm². In the present case, the system was used as a micro coordinate measuring machine.

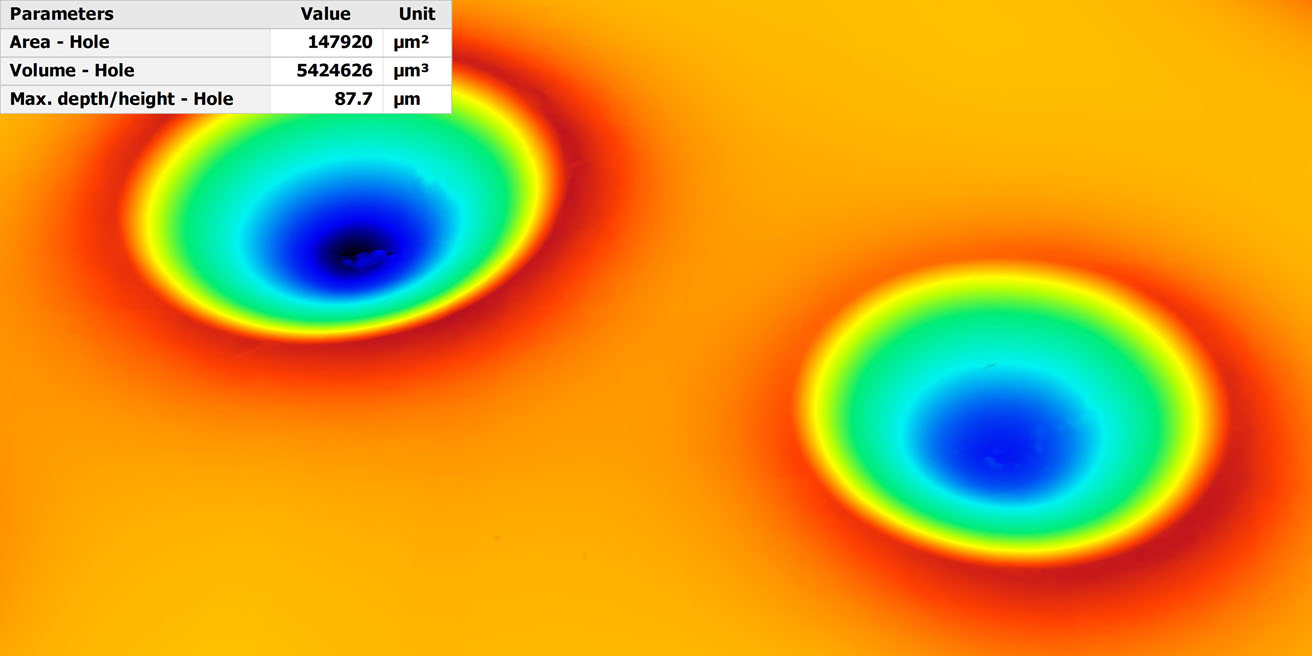

test plate for hardness measurements

Visual evaluation of hardness impressions is not always sufficient. 3D measure-ments allow the depth and volume of the impression to be objectively assessed. For laboratory measurements and research tasks, higher-resolution 20x and 50x lenses are used in systems with a motorized xy positioning table. In combination with a hardness tester, OEM sensors with lower magnification and 10x or 5x lenses are used.

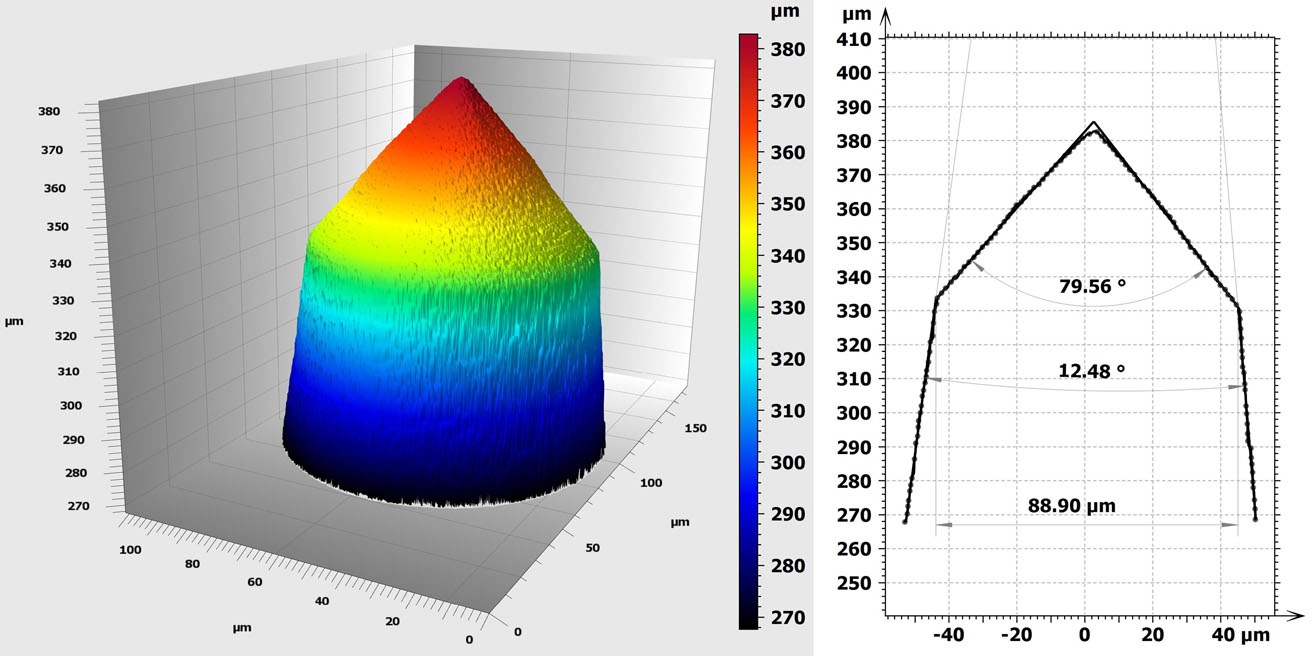

needle for spinnerets

Corresponding needles have a shiny stainless-steel surface. The necessary meas-urement from the tip down requires a very high acceptance angle combined with a very high resolution.

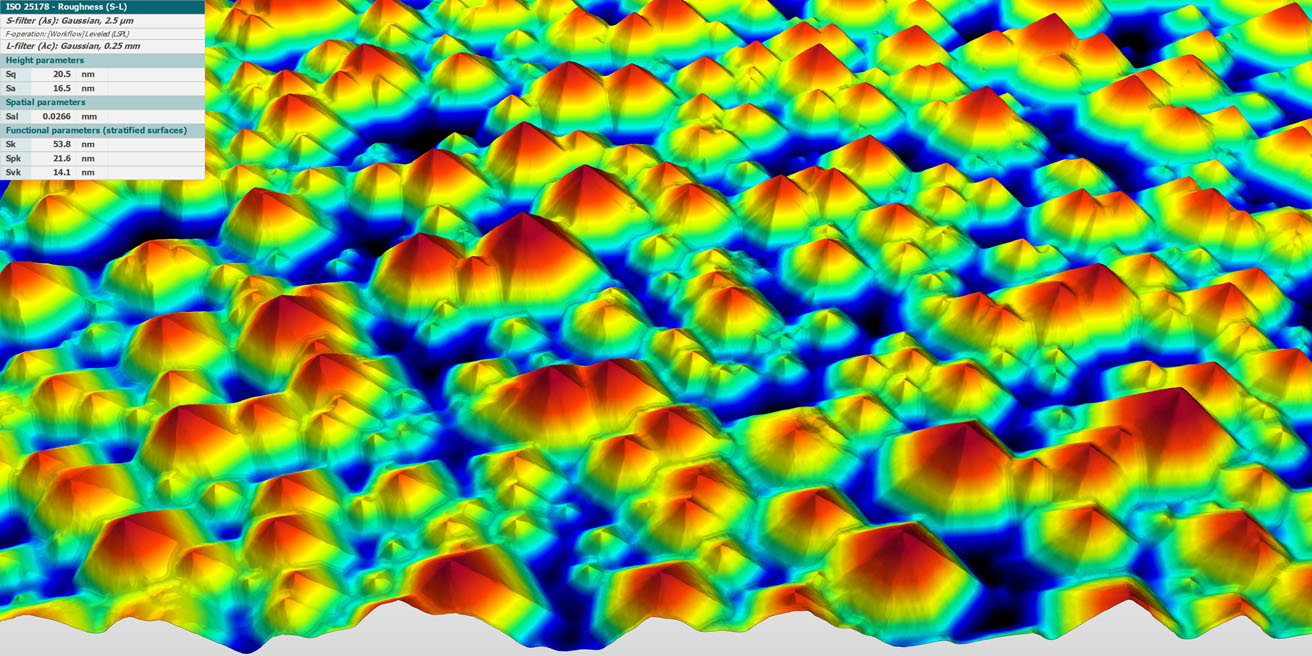

micro crystalline SiC surface

Polycrystalline SiC surfaces have special electrical, thermal, and mechanical proper-ties with a wide range of applications in power electronics, optoelectronics, microe-lectronics, aerospace, and medical use in implants. The transparent, finely structured surfaces require high-resolution measurement and evaluation of larger areas to significantly evaluate the surfaces, assess their suitability for the specific purpose and optimize the manufacturing processes. High-resolution sensors with piezo and 50x objective are required for the measurements.

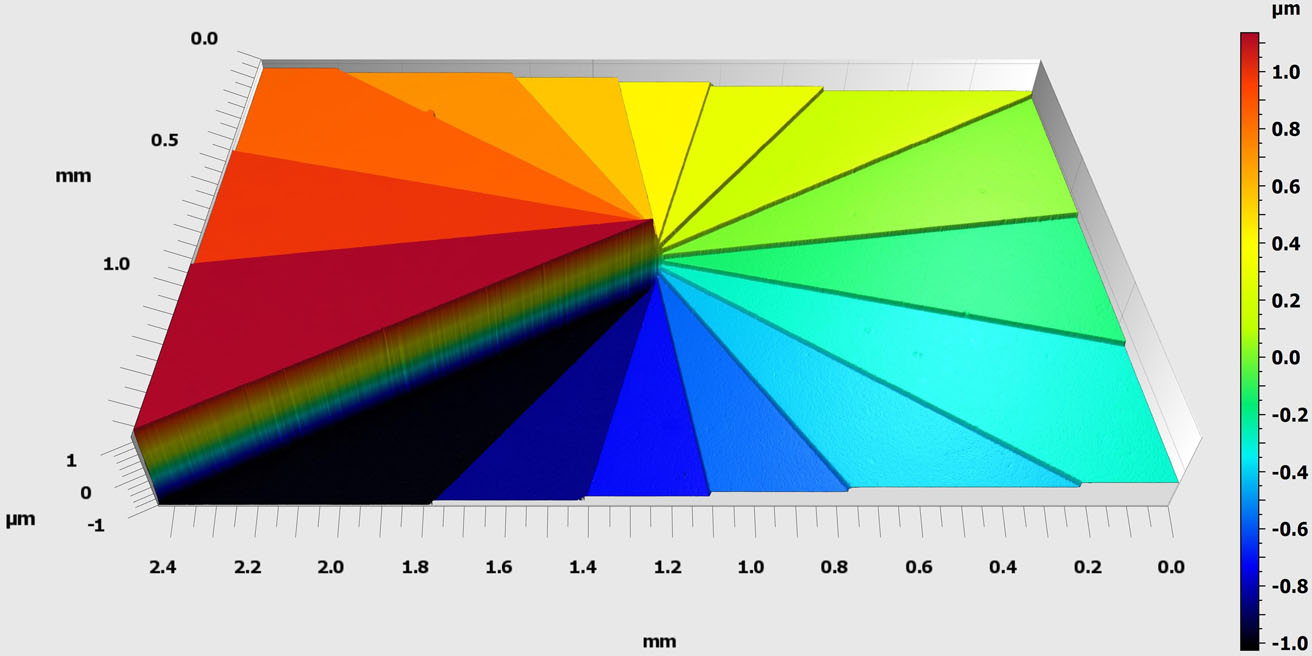

micro spiral staircase

Corresponding test structures for optical - holographic components were used internally for the optimization of EPSI (extended phase shift interferometry) and HD (high density) - EPSI. This combines the ability of high-resolution measurements with sub-nanometer resolution and a very large measuring range in the z axis.